Arcus Workplace Producitivity Innovation Series: A Model for Reinforcing Safe and Healthy Workplaces. Safe and healthy workplaces start and end with the attitudes and behaviours of both workplace parties – employers and workers. There must be a belief that workplace injuries are unacceptable and preventable. Workplace parties need to be aware of their responsibilities and their rights. They must know and respect the hazards of their jobs and they will need appropriate tools, knowledge and training to make their workplaces safe. Finally, some workers and employers will require support to fulfill their roles.

Employers need to believe all workplace injuries are preventable and unacceptable. They need to be aware of their responsibilities and make health and safety a management priority. They also need to understand their workplace hazards and create a safe work environment. They also need access to support to fulfill their responsibilities. Workers need to believe all workplace injuries are preventable and unacceptable. They need to be aware of their health and safety rights and identify and respect the hazards of their job. They need to be educated and trained in safe work practices and be primary guardians of their own safety. And they need to have the support necessary to exercise their rights.

The five Ways the Prevention System Will Change

Now, more than ever, is the time to eliminate costs associated with workplace injury, by making preventive health and safety practices a priority. The repercussions are significant with eighty to a hundred traumatic fatalities a year, each tragedy flying below the radar of public consciousness and 1,600 allowed lost time injuries each week. The key avenues of influence for health, safety and wellness are companies, HSAs and government. Clearly, these organizations can influence the organizational culture, physical work environment and personal health resources. In the area of organizational culture, the importance of flexible hours, a supportive management and an equitable work-life balance have a significant impact on the culture. The physical work environment may be driven by ergonomics, a superior fire safety plan and the quality of indoor air. And in the area of personal health resources, onsite exercise facilities, preventative flu shots at work and programs to address health related activities such as diets and smoking cessation may be effective.

According to Industrial Safety and Hygiene News (April 2001), the five best persuasive arguments are the values of top leadership (37%), the need to comply with OSHA (35%), The need to cut injury/illness rates (34%), an emphasis on consistent corporate culture (30%) and importance of maintaining good relations with workers (29%). And the least persuasive are profitability/earnings (13%), workers comp cost (12%), community relations (11%), need to protect brand image/equity 911%) and need to protect quality (8%).

We also know that the health and safety continuum is driven by compliance, performance and excellence. See exhibit on right. In the area of compliance, adherence to laws, lost time injury and fines and penalties are most effective. Influencers of superior performance include business improvement plans, decrease compensation premiums and injury costs an enhanced productivity. And key drivers of excellence relate to brand value, social responsibility and share price. A key driver of the success of the offering will depend on the clusters of members in each of the three areas of the health and safety continuum of Compliance, Performance and Excellence.

The new lexicon in occupational health and safety is driven by awareness and understanding of key drivers of excellence. These relate to several areas including a healthy workplace, engaged employees, workplace culture, values and beliefs and a commitment to continual improvement. Other areas that have a broader long term impact include enterprise risk management, the social responsibility agenda, a proactive sustainability plan, a commitment to productivity, quality and shareholder value.

It is clear from secondary research that there is some indication of the business community increasingly recognizes HSE as a business imperative in context of use of health, safety, and the environment (HSE) metrics as a indicator of performance and publication of HSE results. Moreover, the investor community, namely financial analysts, investors and the media are increasingly asking questions about the performance of companies in the area of HSE. Another driver has been growing regulatory penalties and civil awards in HSE cases.

Arcus research indicates that the key drivers of success are about creating the right culture, setting corporate standards and expectations, establishing an HSE management system and integrating policies into operations and encouraging compliance with training and education. Creating the right culture: As per Mr. Thomas Vulpe at the Centre for Intercultural Learning, culture is “A way of life, the sum total of one’s philosophy, beliefs, norms, values, morals, habits, customs, arts and literature…”. It is a system of values and norms that are shared among a group of people and that when taken together constitute a design for living.

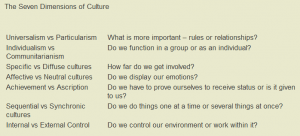

The Seven Dimensions of Culture

We believe that there are five strategic priorities that drive the success of HSE initiatives:

- Create a pervasive culture

- Setting corporate standards and expectations around synergies

- Establishing an HSE management system

- Integrating HSE policies into operations

- Encouraging compliance with training and education

1. Create a pervasive culture

Effective communication breaks down barriers and provides clarity, sets expectations, avoids misunderstandings and deals with myths and stereotypes. It paves the way for transformation and change. Managing a culture change process will require an in-depth understanding and assessment of the diverse dimensions of each organization’s culture, differences in values and communication systems.

This is manifested in the following culture change cycle: Corporate culture, communication culture, business culture and organizational behavior affect the strategies an organization uses to achieve inclusion in the workplace. Why inclusion? Because failure to recognise or value cultural diversity can create problems. We know from several case studies related to culture change that issues arise when organisations adopt a “one-size-fits all” approach within their organizations or for an entire industry. The fact is no two individuals, organizations or industries respond in the same way to the same stimulus. Without recognizing or valuing the cultural imperative that is unique to each organization, a culture change process is likely to fail.

Communication is important because culture differences between organizations affect how we send, receive and interpret information. This difference is more pronounced if organizations have strong and ingrained work processes and systems in place where new processes may meet with significant resistance with a “not invented here” rationale.

2. Set corporate standards and expectations around synergies

When synergy is well managed, it can be a boon, creating additional value with existing resources. But when its poorly managed, it can undermine an organization’s confidence and erode the trust among business units as well as between the units and the corporate centre. Synergy’s upsides are real, but so are its downsides. And the only way for managers to avoid the downsides is to rid themselves of the biases that cloud their thinking, according to HBR’s review on Corporate Strategy (C. K. Prahalad, Kenneth Lieberthal). The key areas where synergy works especially in HSE are the following:

Shared know how: Units often benefit from sharing knowledge and skills. They may, for example, improve their results by pooling their insights into a particular process, function, or geographic area. The know-how they share may be written in manuals or in policy and procedure statements, but very often it exists tacitly, without formal documentation. Value can be created by simply exposing on set of people to another who have a different way of getting things done. The emphasis that many companies place on leveraging core competencies and sharing best practices reflects the importance attributed to shared know-how.

Coordinated strategies: It sometimes works to an organization’s advantage to align the strategies of two or more businesses. Divvying up markets among units may, for instance reduce interunit competition. And coordinating responses to shared clients may be a powerful and effective way to counter barriers to increased efficiencies and superior customer service. Striking the right balance between corporate intervention and business-unit autonomy is not easy. It requires a consistent and coordinated strategy with appropriate benchmarks of performance.

Vertical integration: Coordinating the flow of services from one unit to another can reduce inventory costs, speed product development, increase capacity utilization and improve market access. Well managed vertical integration can yield particularly large benefits.

Combined business creation: The creation of new businesses can be facilitated by combining know-how from different units, by extracting discrete activities from various units and combining them in a new unit, or by establishing internal joint ventures or alliances. As a result of the business world’s increased concern for corporate regeneration and growth, several companies have placed added emphasis on this type of synergy.

3. Establishing an HSE management system

Knowledge of safety, health and environmental issues and procedures will not protect people, property and the environment. The key to success is the establishment of an effective safety, health and environmental management system. Such a system which involves all levels of the organization from the ranking manager to, and including all employees, will continually increase awareness and protect people, property and the environment. The key attribute of a successful HSE management system is top management commitment and participation. This is the driving force to achieve all organizational health, safety and environmental objectives.

4. Integrating HSE policies into operations

Why do we often manage employee safety and health in different ways? At many facilities the safety-health manager is sometimes has a limited role. Often the ranking manager will assign responsibility for managing safety and health to an employee who is nearing retirement, or to a supervisor or middle manager who has little or no safety training as a collateral duty. Even for large organizations, who supposedly have good safety and health management systems, an individual who may be well qualified to manage will often be given the responsibility of managing environmental, health and safety without the benefit of a staff, or authority to delegate. The individual’s management effort is restricted to chairing the safety committee and making recommendations. The key drivers of success require four stages of plan, organize, lead and control in a continuous feedback loop. (Effective Environmental, health and safety management using the team approach by Bill Taylor).

Three HSE functions need to be considered in the HSE management system:

- Setting policy

- Planning, measuring, reviewing, auditing

- Ensuring effective implementation of the health and safety system.

The first function refers to formulating and developing policy, including key objectives, and reviewing progress against these objectives. Senior executives at the organization should be policy makers and responsible for the coordination and monitoring of the implementation of the policy.

The second function refers to planning, measuring reviewing, and auditing health and safety activities to meet legal requirements and minimize risks. Planners are responsible for the function in the system and should cover activities such as setting goals, establishing management arrangements, risk control, workplace precautions and performance standards. They also coordinate the activities of specialists; ensure participation of employees and health and safety representatives. They also need to keep themselves updated on health and safety legislation, standards and good practices, as well as with other relevant management practices.

Finally, the third function refers to ensuring effective implementation of plans and reporting on performance. Implementers are responsible for this function. They should deal with the implementation of what planners produce, plus the provision of physical and human resolves, information and feedback on system performance, as well as ensuring communication and participation at all levels of health and safety activities.

5. Encouraging compliance with training and education

A number of events in nuclear installations in German reported in recent years have been attributed to the organizational weaknesses and the behaviour of the personal with respect to their attitudes to towards safety. These events bring to fore the relevance of human factors that define a “safety culture”. While there are a number of tools available for measuring the safety culture status, the problem of how to enhance safety culture and communicate the relevant information developed by high level experts to the responsible staff has not been answered satisfactorily.

The insights from a paper by the former inspector general of Nuclear safety in France (EdF), Pierre Tanguy, states that putting the safety policy into practical use needs to be supported by the development of “pedagogical manuals” to encourage the desired open communication and to let the following findings come into effect:

The staff will only conscientiously follow the path of duty if they accept the general views and objectives and if they believe that they can positively contribute to them.

The reasons behind the regulations and procedures at the individual workplaces ought to b understood by everyone. A progress towards “Total Quality” can primarily be achieved through proposals from the personnel at their individual place of work

In order to facilitate the detection of weak points related to safety, a quality safety plan and a “guide for events analysis” is required to not only support the detection of contributing factors but also help to assess the possible risks of an event in group discussions with the personnel involved. With respect to the assessment of a safety culture campaign and in order to sustain the status achieved, the analysis of “sudden events” performed under professional guidance by persons involved is the optimum method of measuring progress. In summary, the emphasis of a safety culture needs to be on the relevance of the work force’s active participation in ensuring the success of the safety culture campaign with basic knowledge about requirements of safety culture and correct handling of “human errors”. It is also important to guide employees towards an appropriate casual analysis of “human errors” with the deployment of proposals to overcome these detected obstacles and problems and to enhance the organizational framework.